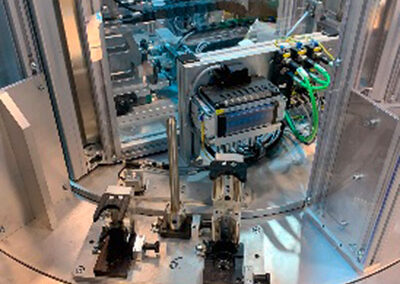

Oil filling station

This is a 12-station machine, including four operator stations, with two rotary tables for automotive shock absorber assembly. Turntable 1 for the assembly of inner tube of the shock absorber, and turntable 2 for the assembly of inner and outer tube, including oil filling, press in the seal pack and other processes.

REQUIREMENTS

- Cycle time 18 seconds per piece

- Horizontal and vertical accuracy of each working station

- Transfer of workpieces between two rotary tables and data transfer

PROCESSES

- Loading inner tube, piston rod and spring

- Bottom valve check with vision sensor

- Insert piston rod

- Press spring in

- Bottom valve handling

- Insert inner tube into outer tube

- Oil filling

- Seal pack insert and press-in

- Unloading

SYSTEM DATA

Place of manufacture: China

Industry: Automotive

Operating location: China

Year of construction: 2021

Contact

Rosengasse 18,

D-96271 Grub am Forst

+49 9560 9223 0

info@unimatic-co.de