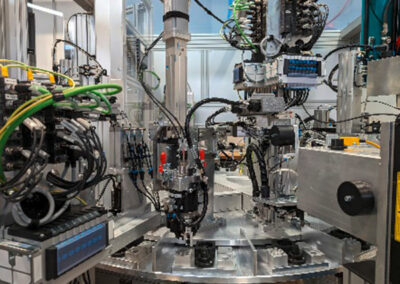

SEAL ASSEMBLY SYSTEM

The system installs a sealing package in shock absorbers. All individual parts are manually inserted into the workpiece carrier by a worker and cycled through the assembly stations using a rotary table. OK parts are marked with laser engraving.

REQUIREMENTS

- High variance and flexibility

- Caulking process for sealing the assembly

PROCESSES

- Querying all individual parts

- Assembly with process monitoring

- Laser marking

- OK/NOK withdrawal

SYSTEM DATA

Place of manufacture: Germany

Industry: Automotive

Operating location: Romania

Year of construction: 2023

Contact

Rosengasse 18,

D-96271 Grub am Forst

+49 9560 9223 0

info@unimatic-co.de